In an era where global supply chains are both a boon and a bane for manufacturing sectors worldwide, the concept of “import replacement” emerges as a beacon of strategic advantage. This approach, advocating for the substitution of imported goods with locally produced alternatives, isn’t just about national pride; it’s a pragmatic pathway towards economic resilience, innovation, and sustainability. Central to empowering this shift is the domain of precision mechanics – a discipline that ensures the meticulous design, manufacturing, and functionality of mechanical components and systems with supreme accuracy and reliability.

The Imperative of Import Replacement

In today’s interconnected global economy, reliance on overseas suppliers for critical components and technologies presents a significant vulnerability. Disruptions in the supply chain – be it due to political unrest, pandemics, or logistical challenges – can stall production lines, inflate costs, and erode competitiveness. Import replacement strategies mitigate these risks by fostering a self-sufficient industrial base, reducing lead times, and securing a more predictable and controllable supply chain.

Moreover, import replacement is integral to bolstering the local economy. By redirecting funds that would otherwise flow abroad towards domestic production, countries can stimulate local employment, nurture industrial capabilities, and retain a larger share of economic value within their borders. This approach also aligns with environmental objectives by diminishing the carbon footprint associated with long-distance transport of goods, thereby contributing to sustainability goals.

The Role of Precision Mechanics in Import Replacement

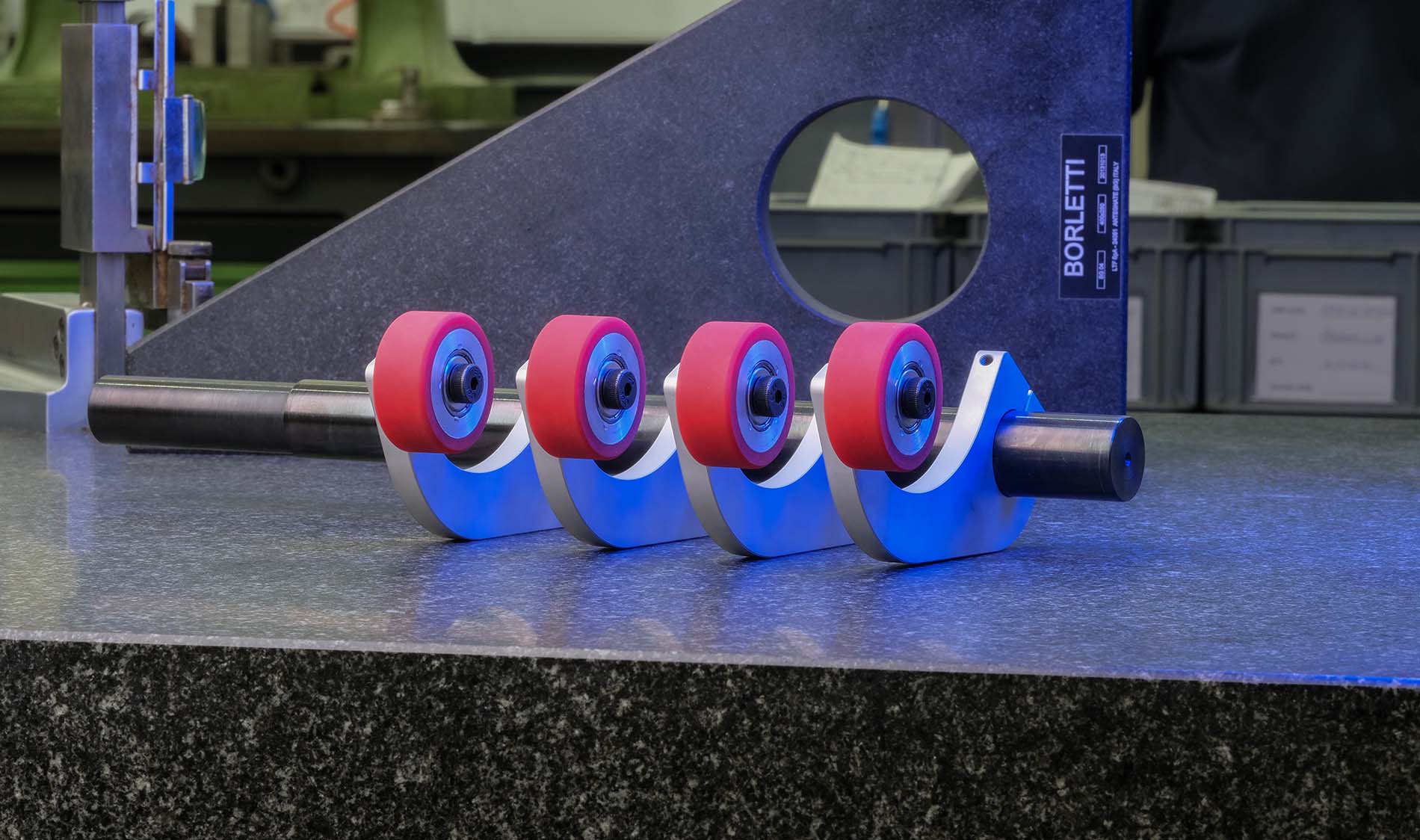

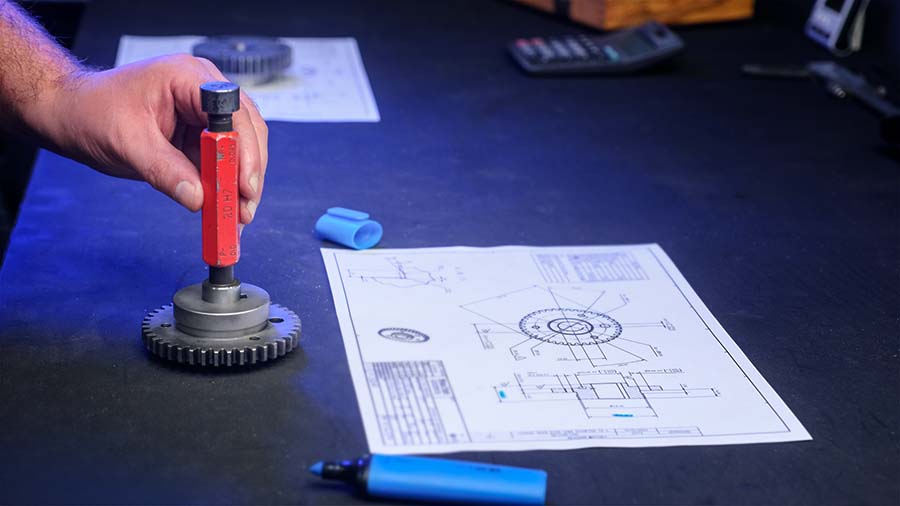

At the heart of successful import replacement initiatives lies the field of precision mechanics. This engineering discipline, focused on the creation and application of components and machinery with exact tolerances, is crucial for the high-quality, reliable production necessary to compete with imported goods. Precision mechanics enables the manufacture of complex, high-performance products that meet stringent standards, from automotive and aerospace parts to medical devices and electronics.

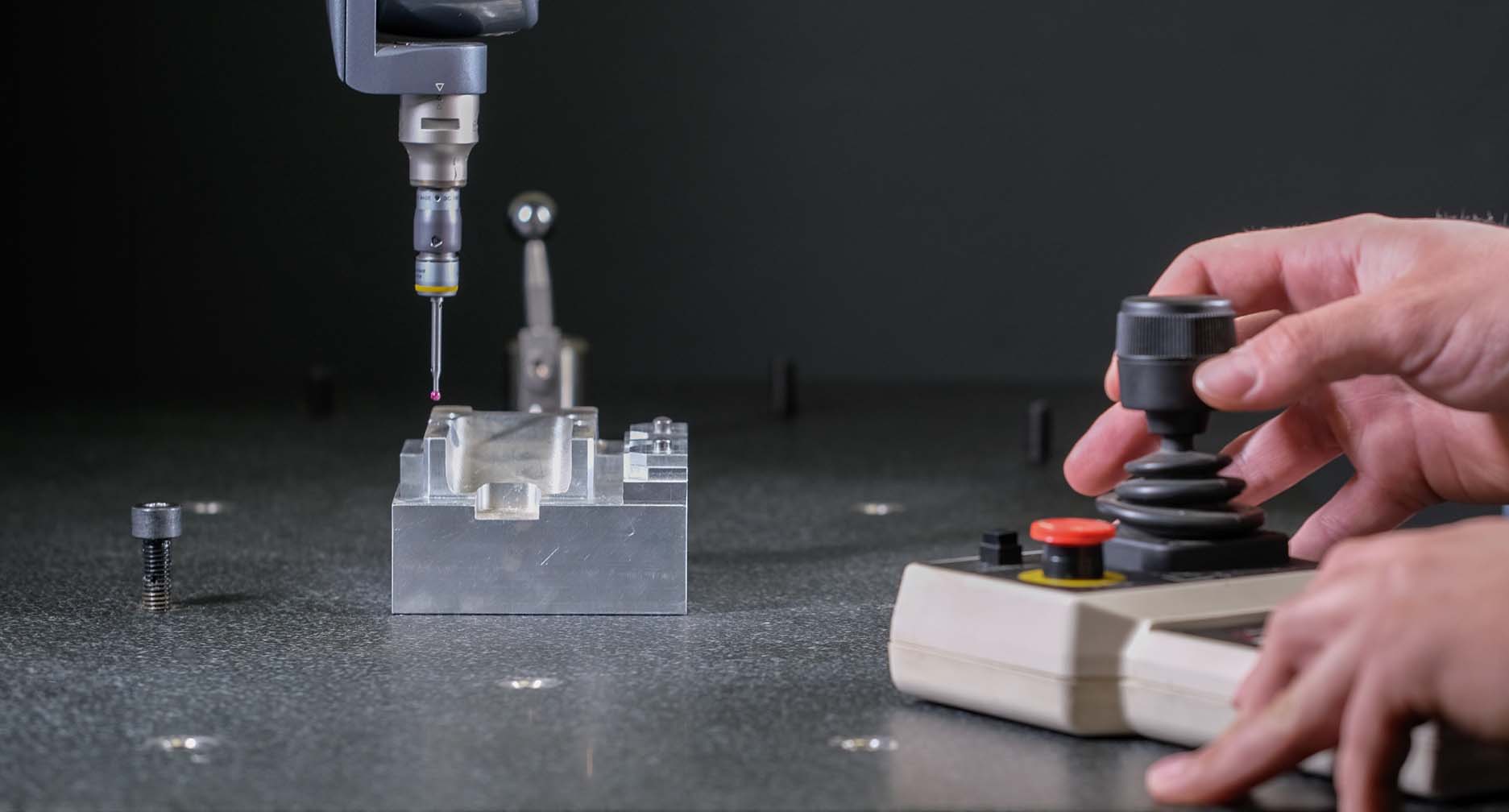

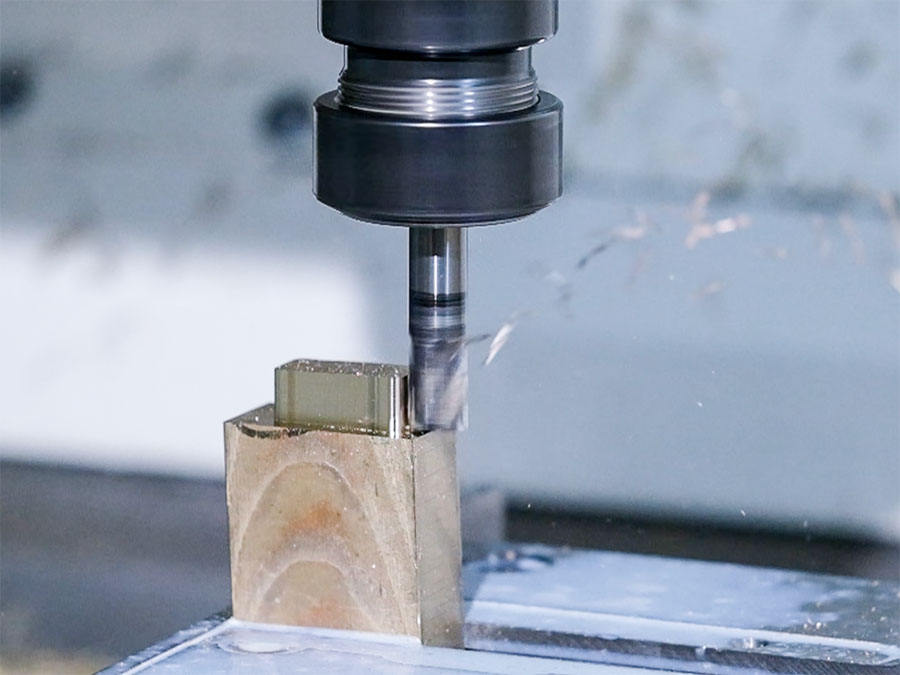

Investing in precision mechanics capabilities facilitates the development of advanced manufacturing technologies, including CNC machining, 3D printing, and robotics. These technologies are pivotal in achieving the levels of efficiency, scalability, and quality required for competitive local production. Furthermore, precision mechanics fosters innovation by encouraging the design and creation of novel products and processes, thereby enhancing a nation’s industrial and technological sovereignty.

Strategies for Enhancing Import Replacement through Precision Mechanics

Enhancing import replacement efforts through precision mechanics involves a multifaceted strategy. Key components include:

- Investment in Education and Training: Developing a skilled workforce proficient in precision engineering techniques is essential. Tailored educational programs and partnerships with technical institutes can equip future engineers and technicians with the necessary skills.

- R&D and Innovation Support: Government and private sector investment in research and development can spur innovation in precision mechanics. Incentives for developing new materials, processes, and products can drive technological advancements and improve competitive advantage.

- Infrastructure and Technology Upgrades: Modernising manufacturing facilities with state-of-the-art precision engineering equipment ensures the production capabilities needed to replace imports effectively. This also includes adopting digital technologies like AI and IoT for smarter, more efficient production processes.

- Collaboration and Networking: Fostering collaboration between manufacturers, universities, and research institutions can accelerate the transfer of knowledge and technology. Networking opportunities through conferences and consortia can also promote best practices and innovation in precision mechanics.

- Policy and Regulatory Support: Government policies that support local manufacturing, such as tax incentives, subsidies for technology upgrades, and import restrictions on certain goods, can enhance the competitiveness of domestic industries.

The Path Forward

As we navigate the complexities of global supply chains and strive for greater industrial autonomy, the synergy between import replacement and precision mechanics offers a promising path forward. This strategic alignment not only secures supply chains but also propels innovation, economic growth, and sustainability.

The journey towards mastering precision mechanics and enhancing import replacement strategies is not without its challenges. It requires concerted effort, investment, and collaboration across the public and private sectors. However, the rewards – a resilient economy, advanced industrial capabilities, and a reduced environmental impact – are well worth the endeavour.

In conclusion, the fusion of import replacement and precision mechanics is more than a strategic choice; it’s a commitment to building a sustainable, innovative future. By investing in the skills, technologies, and policies that support this integration, nations can safeguard their industrial bases, stimulate local economies, and pave the way for a more self-reliant, sustainable future.

About MegaPack Engineering

MegaPack Engineering, with its roots firmly planted in the field of precision mechanics, stands as a beacon of innovation and reliability in the engineering sector. Our expertise spans across designing, manufacturing, and implementing high-quality, precision-engineered solutions tailored to meet the rigorous demands of various industries. By championing the cause of import replacement, we not only aim to enhance the resilience and efficiency of local manufacturing but also to contribute to the economic and environmental sustainability of our community.

Whether you’re seeking to reduce dependency on imported components, looking for bespoke precision-engineered parts, or need expert guidance to refine your manufacturing processes, MegaPack Engineering is your partner in achieving excellence. Our dedicated team of engineers and technicians are committed to providing you with solutions that not only meet but exceed your expectations.

For inquiries on how we can assist your business in mastering precision mechanics and bolstering your import replacement strategies, visit MegaPack Engineering. Let’s innovate, produce, and prosper together.