In industrial settings, operational continuity is the backbone of productivity and profitability. Unplanned downtimes, particularly in production lines, can lead to substantial financial losses and damage to customer relationships. This is where the efficiency of custom spare parts logistics becomes pivotal. Mega Pack Engineering recognises the critical nature of these challenges and offers solutions designed to minimise production downtime and maximise operational efficiency.

Understanding Production Downtime and Its Implications

The True Cost of Downtime

Every minute a production line remains inactive, potential revenue streams dry up. Industry reports suggest that for many manufacturers, the cost of downtime can reach thousands of dollars per minute. These costs are not just immediate losses but can also have long-term repercussions on business reputation and customer trust.

The Role of Quick Turnaround on Custom Spare Parts

Having a reliable system for the quick turnaround of custom spare parts is essential. It’s not merely about having the right parts in stock; it’s about how swiftly and efficiently these parts can be delivered and installed to resume operations. Mega Pack Engineering focuses on ensuring that these critical components are manufactured and delivered within 24 hours, aligning with the urgent needs of the industry.

Mega Pack Engineering: Your Partner in Reducing Production Downtime

Streamlined Processes for Rapid Response

At Mega Pack Engineering, our logistics and production systems are fine-tuned to respond swiftly in the event of production halts. Our commitment to quick service begins with a thorough understanding of our clients’ unique operational needs, allowing us to anticipate and prepare for potential part requirements.

Customised Solutions for Every Need

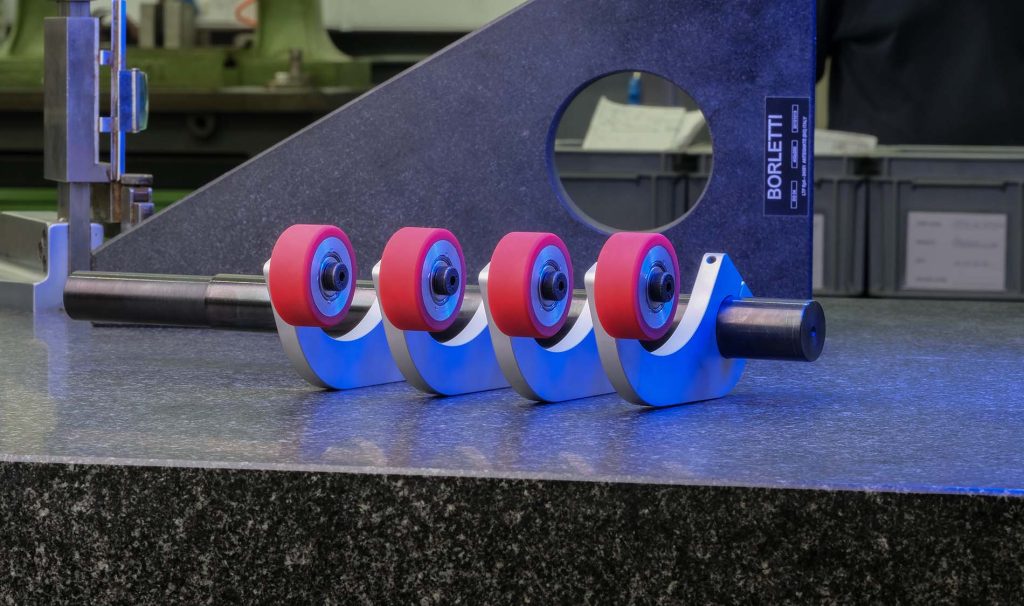

Understanding that each production line is unique, we tailor our spare parts supply not just to fit the machine but to integrate seamlessly with specific production processes. This bespoke approach ensures that the parts are not only a technical fit but also optimise the performance and longevity of the machinery. This is why Mastering Precision Mechanics is essential.

Strategic Planning and Preventive Measures

Importance of Proactive Measures

While addressing emergencies is crucial, the significance of preventive strategies cannot be overstated. By collaborating with Mega Pack Engineering, industries can implement a proactive approach, identifying potential failure points, and ensuring that spare parts are either on-hand or can be manufactured swiftly.

Inventory Management and Predictive Analysis

Leveraging advanced analytics and inventory management systems, we help clients predict when and which parts are likely to be needed. This predictive capability allows for better planning and faster reaction times, thus reducing the likelihood of prolonged downtimes.

Enhancing Production Efficiency with Swift Spare Parts Supply

Beyond Just-In-Time: A Look at Just-In-Case

In the pursuit of lean manufacturing, the concept of ‘just-in-time’ inventory has been prevalent. However, when it comes to spare parts, a ‘just-in-case’ strategy is often more appropriate. This approach ensures that parts are available when needed most, thereby avoiding the pitfalls of zero-inventory policies.

Case Studies of Efficient Turnarounds

To highlight the effectiveness of our approach, consider the case of a client who experienced a critical failure in their conveyor system. With our rapid response service, the required custom part was designed, manufactured, and delivered within 24 hours, resulting in minimal downtime and resumed operations quickly.

Safeguarding Your Production with Mega Pack Engineering

In today’s fast-paced industrial environment, being prepared for any contingency with a reliable spare parts strategy is not just an option—it’s a necessity. Partnering with Mega Pack Engineering ensures that your production lines are safeguarded against unexpected downtimes, keeping your operations smooth and financially viable.

For more information on how our rapid response capabilities can benefit your business, contact Mega Pack Engineering today. Let us help you maintain continuous production flows, optimise efficiency, and enhance your bottom line. Because in industry, every second not only counts—it costs.