In today’s fast-paced and ever-evolving manufacturing landscape, businesses are perpetually in pursuit of strategies that not only enhance operational efficiency but also ensure financial prudence. Amidst this quest, the concept of refurbishing old machinery emerges as a beacon of sustainability, technological adaptability, and, importantly, cost-efficiency. This practice, often overlooked in the rush towards acquiring the newest technologies, offers a pragmatic solution to companies aiming to maximise the utility and lifespan of their existing assets. Refurbishing, in essence, involves updating or repairing old machinery to restore its functionality and efficiency, often incorporating modern technological advancements.

The Financial Logic Behind Machinery Refurbishment

Cost-Efficiency: A Strategic Imperative

Refurbishing existing machinery serves as a beacon of financial wisdom. The exorbitant costs associated with acquiring new machinery can significantly deplete capital resources. In contrast, refurbishment emerges as a fiscally responsible alternative, requiring merely a fraction of the expenditure necessitated by new purchases. This strategic choice extends machinery life, optimises the return on initial investments, and moderates depreciation rates, allowing businesses to leverage their assets fully.

Boosting Efficiency Through Upgrades

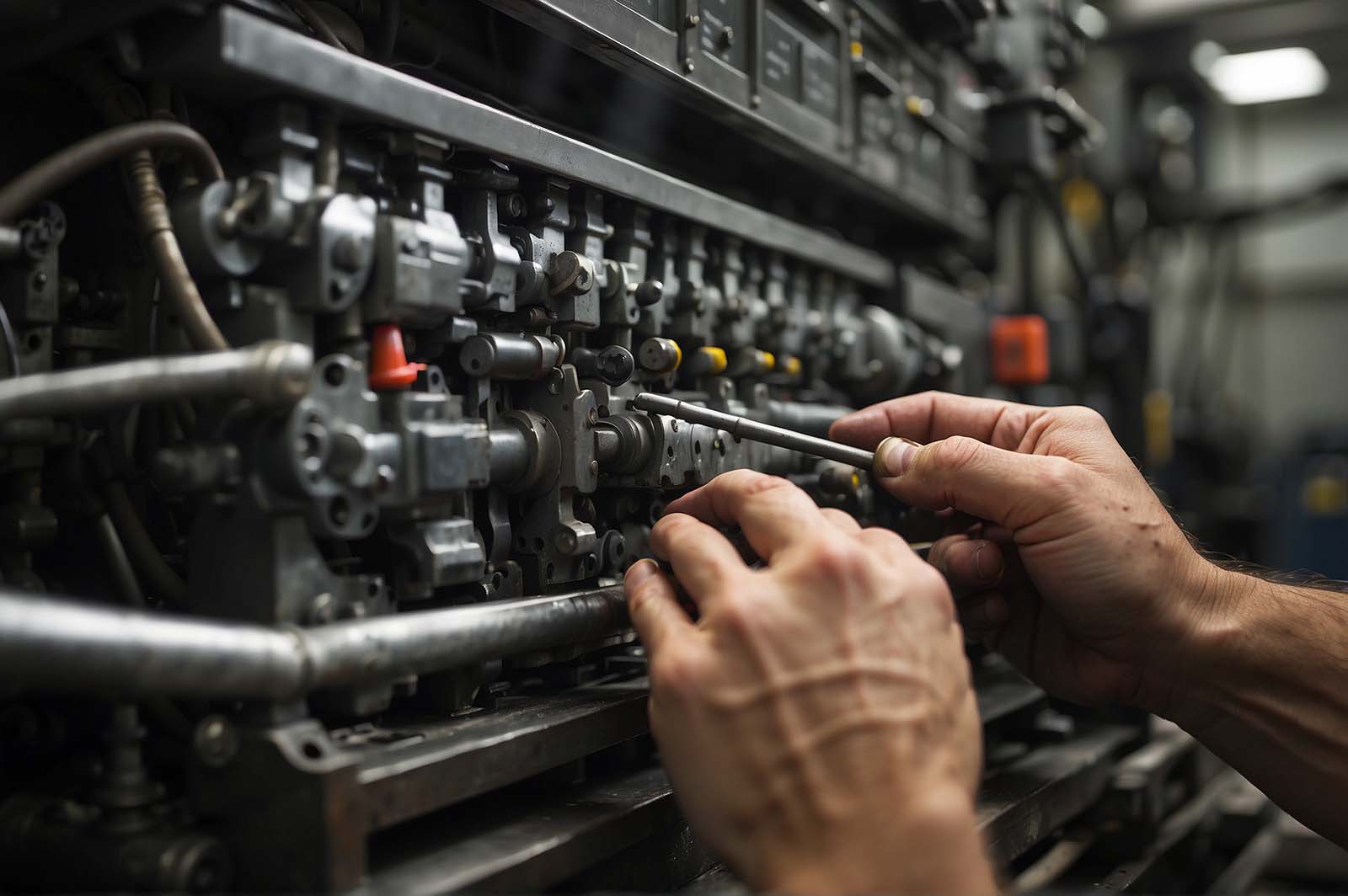

The refurbishment process opens avenues for integrating contemporary technologies into existing machinery, bridging the gap between dated and cutting-edge equipment. This integration can lead to significant enhancements in operational efficiency. Furthermore, customisation during refurbishment allows machinery to be precisely tailored to specific production requirements, ensuring optimal productivity and efficiency.

The Sustainability Advantage

Mitigating Environmental Impact

Refurbishing machinery underscores a commitment to environmental stewardship. By opting for refurbishment over replacement, businesses can significantly reduce waste and the carbon footprint associated with manufacturing new machinery. This approach aligns with the principles of a circular economy, promoting resource conservation and appealing to the eco-conscious consumer base.

The Synergy of Cost-Efficiency and Sustainability

The refurbishment of old machinery presents a compelling narrative of synergy between cost-efficiency and sustainability. It exemplifies how economic decisions can align with environmental stewardship, creating a sustainable business model that values resource optimisation and efficiency. This synergy not only enhances the financial bottom line but also contributes to a positive environmental impact, reinforcing the company’s commitment to sustainable practices.

Navigating the Refurbishment Process

Assessment and Planning

The refurbishment journey commences with an exhaustive evaluation of the machinery’s current state, identifying areas necessitating updates or repairs. This preliminary step is pivotal in delineating the refurbishment scope, budgetary considerations, and anticipated timelines.

Selecting a Refurbishment Partner

The choice of refurbishment partner is critical. Consider opting for entities renowned for their expertise, experience, and understanding of industry nuances. A competent partner can significantly augment the value and performance of refurbished machinery.

Post-Refurbishment Maintenance

After refurbishment, establishing a rigorous maintenance regimen is indispensable for sustaining operational efficiency and prolonging machinery lifespan. This proactive approach ensures that the refurbished machinery continues to operate at its zenith, epitomising the ethos of maximising investment returns.

Empirical Evidence: Success Stories

Illustrative examples underscore the tangible benefits of machinery refurbishment. A textile manufacturing entity, grappling with budget constraints, embarked on a refurbishment journey, integrating smart sensors and energy-efficient motors into its looms. This strategic move not only curtailed capital expenditure by 40% but also elevated production efficiency by 20%. Another exemplar involves a food processing conglomerate that augmented the lifespan of its packaging machinery by five years through refurbishment, achieving substantial energy savings annually.

The strategy of refurbishing old machinery encapsulates a holistic approach to achieving financial acumen, operational efficiency, and environmental responsibility. It represents a forward-looking perspective, optimising existing assets for future exigencies. For enterprises aiming to maximise returns while adhering to sustainability tenets, refurbishment offers a compelling proposition.

Contemplating the refurbishment of your machinery? Embrace the strategic benefits of refurbishment. Reach out to explore how our solutions can revitalise your capital investments, ensuring cost efficiency and superior operational performance.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.