Custom-Designed Products and Reverse Engineering Excellence

Crafting bespoke parts tailored to your specifications and expertly reverse engineering components for optimal performance. At Mega Pack Engineering, we turn engineering challenges into high-quality solutions.

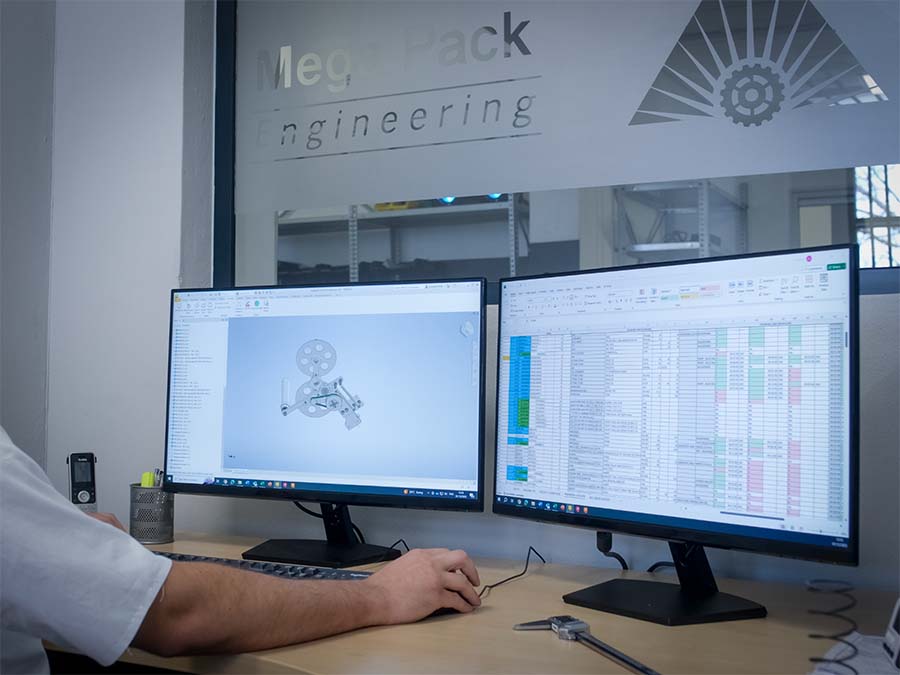

Bespoke Engineering: Your Design, Precisely Realised

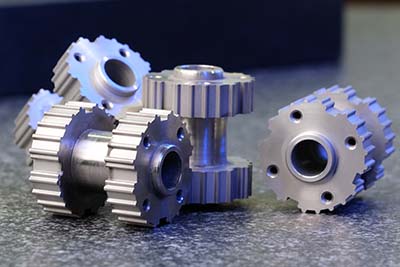

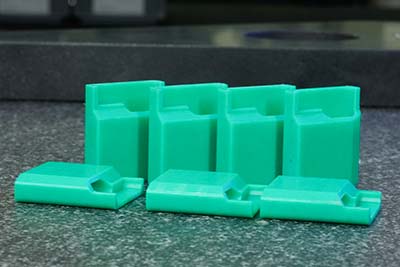

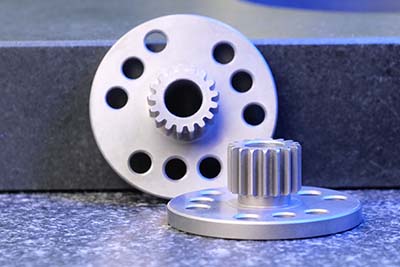

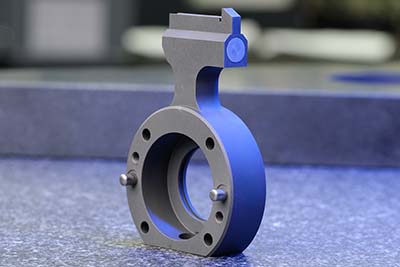

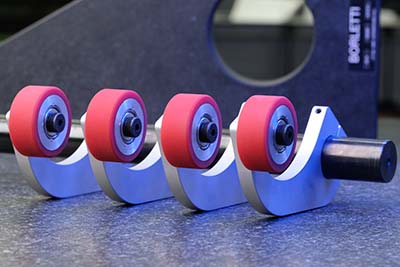

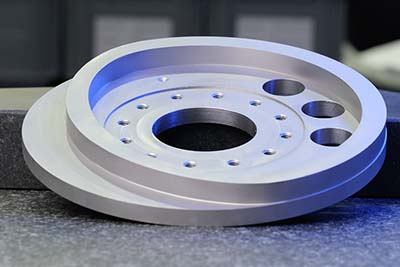

Mega Pack Engineering specialises in bringing your designs to life. Whether it’s a single, custom-made part or a series for large-scale applications, our team works diligently to ensure that each piece meets your exact specifications. Utilising cutting-edge technology and drawing from a wealth of experience, we excel in creating components that fit seamlessly into your projects. From complex machinery parts to intricate tools, our bespoke engineering services are designed to cater to your specific needs, ensuring functionality, durability, and precision.

Reverse Engineering: Reimagining and Replicating with Precision

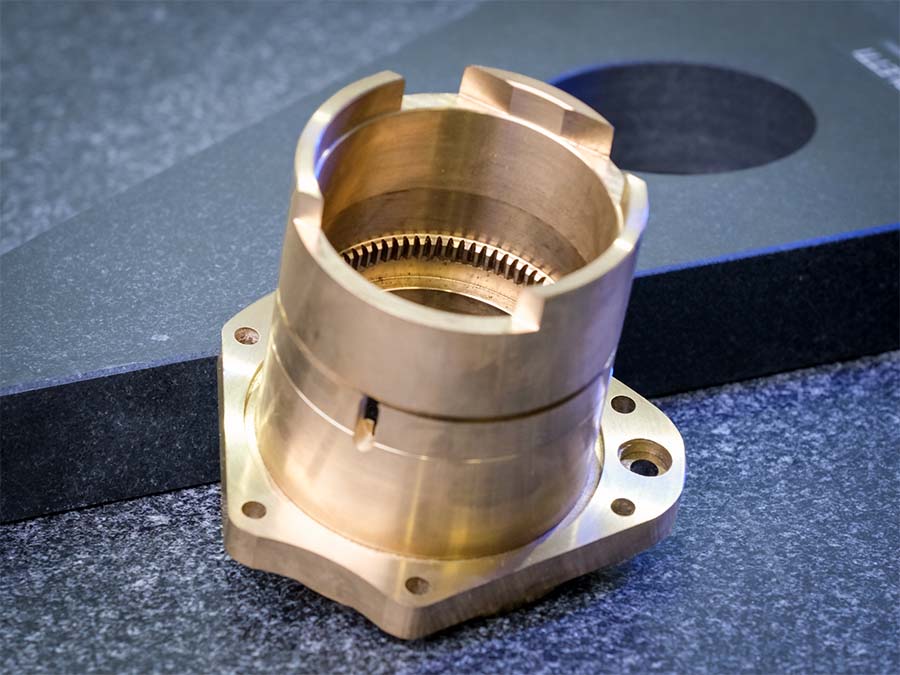

Facing the challenge of replacing hard-to-source or obsolete parts? Our reverse engineering services are the solution. At Mega Pack Engineering, we possess the expertise to analyse, reengineer, and manufacture spare parts for a wide range of applications. This service is particularly valuable for maintaining and extending the life of large plants or machinery, where original parts may be costly or impossible to procure. By accurately replicating existing components, we provide a cost-effective and efficient alternative to overseas sourcing, ensuring that your operations continue without interruption.

Reverse Engineering: Reimagining and Replicating with Precision

Facing the challenge of replacing hard-to-source or obsolete parts? Our reverse engineering services are the solution. At Mega Pack Engineering, we possess the expertise to analyse, reengineer, and manufacture spare parts for a wide range of applications. This service is particularly valuable for maintaining and extending the life of large plants or machinery, where original parts may be costly or impossible to procure. By accurately replicating existing components, we provide a cost-effective and efficient alternative to overseas sourcing, ensuring that your operations continue without interruption.

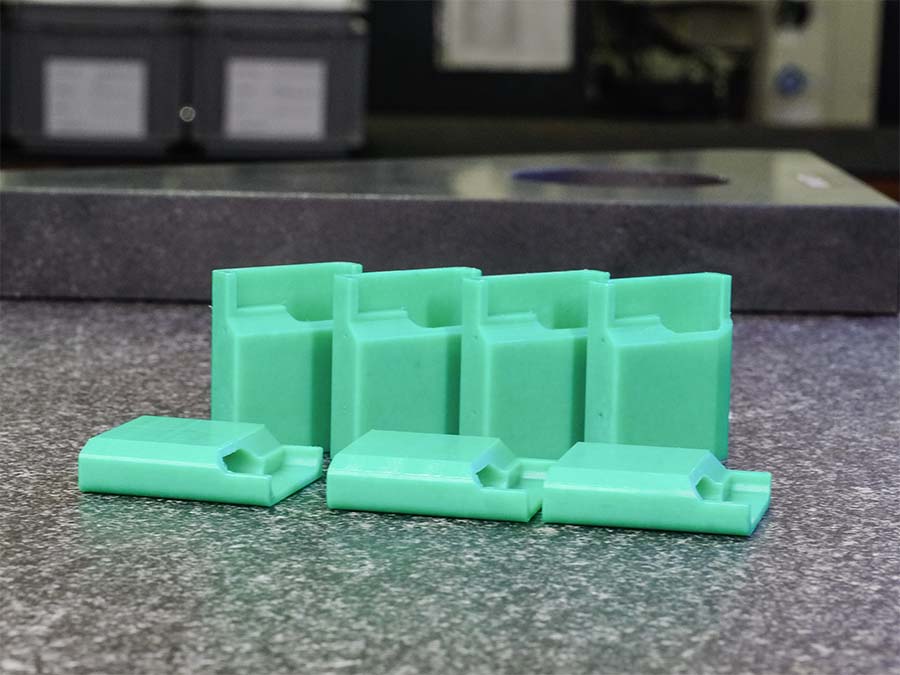

Versatility in Materials: Metals, Alloys, Plastics, and Beyond

Mega Pack Engineering’s expertise extends to a wide range of materials, catering to the diverse needs of our clients. Our capabilities encompass machining and fabricating products using various metals, alloys, plastics, synthetic materials, and even carbon fibre. This versatility allows us to provide solutions that are not just precise and high-quality but also tailored to the specific properties and requirements of the material in use. Whether it’s the strength and durability of metal alloys, the versatility of plastics, or the advanced properties of carbon fibre, our skilled team is equipped to handle projects with varying material demands. By leveraging our material expertise, we ensure that each custom-made product is optimised for its intended application, delivering performance and reliability that meet our clients’ exacting standards.

Get in touch with us

Contact Mega Pack Engineering for bespoke engineering solutions and expert advice. Fill in the form below, and we’ll respond promptly to discuss your specific needs.